Often bearings in wind power turbines lubricated with grease do not last as long as expected, mainly due to the contamination that ends up accumulating in all of their components.

Dust, solid particles and liquid contamination are the main “enemies” of bearings, and therefore it is important to analyse the condition of the grease used, to extend the useful life of the bearing.

The generation of particles that become detached from the bearings is another of the priority aspects in an analysis of the grease in service, which is usually known as the wear of the bearing.

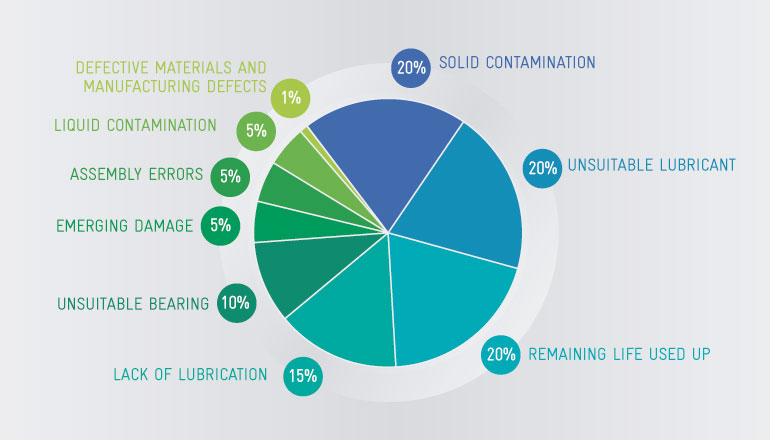

Figure. Cause of faults in bearings

The useful life of a bearing is calculated using the principle L10, “the minimum life expectancy”, which means that 10% of bearings develop defects before the end of the estimated total useful life.

The consistency of the grease, as well as the amount of additives that remain in the grease help define the greasing frequency and the amount of grease necessary in the bearing for it to achieve the anticipated duration.

Analyse the state of the grease in service to diagnose the condition of the bearing.