“Excellent Industrial Lubrication” requires certain concepts to be changed to help enhance the reliability of machinery. What we knew as “lubrication servicer” is now a qualified industrial lubrication technician.

Industrial lubricants are no longer a disposable product and have become a component to manage, an asset that must last as long as possible in optimum conditions, while working in machinery. To achieve this, the industrial lubrication technicians have the following key elements:

– Lubrication requirements of machinery

– Selection of industrial lubricants

– Rationalisation of lubricants

– Purchase of lubricants, filters, gaskets, etc.

– Reception thereof, quality control and concerted quality

– Storage

– Operation

– Application

– Maintenance and contamination control

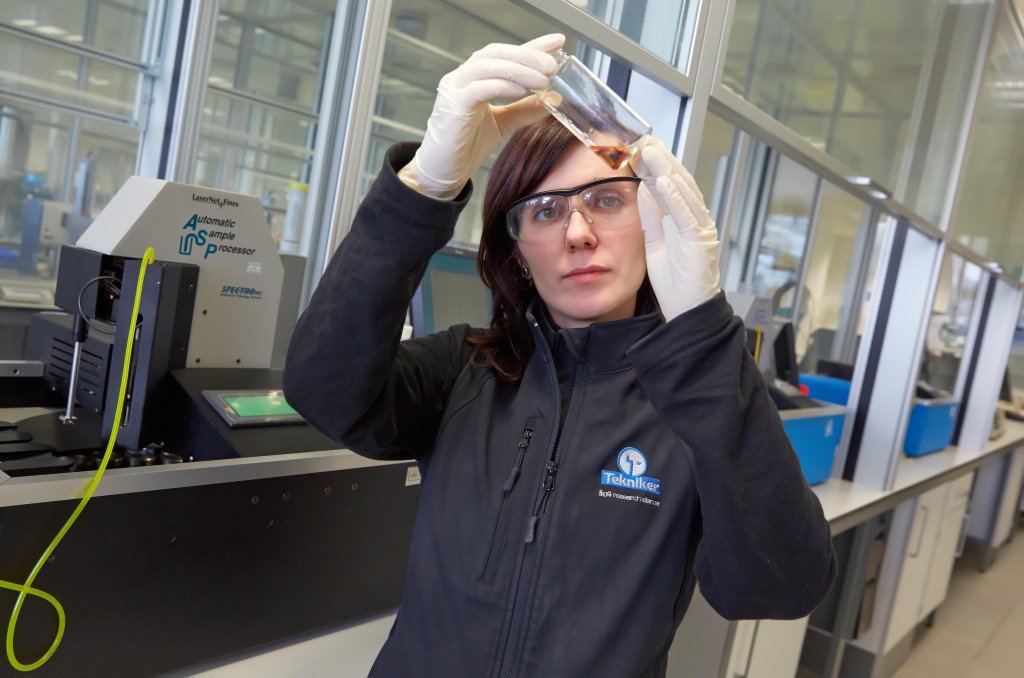

– Analysis of oil, aqueous fluids, greases, etc.

– Their care

– Appropriate management of used products (remember that they are toxic and dangerous waste)