It is difficult to imagine a machine or engine running without grease, since most machines and motors require lubricating grease to operate in good conditions.

However, the condition of the grease must be monitored to prevent degradation during the life of the machines and motors and to prevent them from stopping while they are in operation.

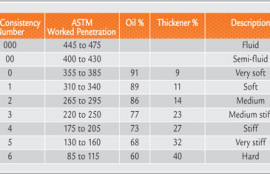

For example, hardened grease is an obvious sign that the grease has lost some of the oil in its composition due to mechanical work or high revolutions. And a loss of consistency may indicate degradation due to excess temperature or mixing with incompatible grease.

It is also important to inspect the grease during maintenance operations to ensure that it is not contaminated by external agents such as water, dust or worn metals.

Lubricating greases also degrade with temperature, pressure and load during working conditions.

Properly setting re-lubricating frequencies is key to avoiding grease degradation and consequently failure of the engines and motors in operation.