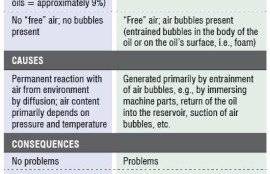

Often, the selection of engine oil is done incorrectly. For this reason, it is very important to take the oil manufacturers’ recommendations into account and to read them carefully with regard to the nature of the gas and its composition.

When using landfill gas or biogas as a fuel, the selection process is complex as its composition can vary significantly, even when it is produced at the same location. For this reason, it is important to carry out periodic assessments of its composition, this way the changes in the behaviour of the lubricant in operation can be anticipated.

However, with other types of gases, such as natural gas, selection is somewhat less complicated as its composition is clearly defined by the specifications established by official organisations.

The continuous evolution of gas engines themselves brings with it new and harsher demands for lubricating oil, which cannot always be met by a traditional mineral-based lubricating oil.

A few decades ago, the manufacturers of lubricating oil initiated a process of incorporating synthetic base oils or those derived from improved refining into the composition.

In parallel, the different additives which make up the composition of lubricants have also experienced a positive evolution towards the search for improvements in the natural properties of the base oil.

A perfect balance and synergy between the base oil and the additive package is key when it comes to the efficient operation of the engines.

An inadequate selection of lubricating oil does not necessarily cause immediate damage to the engine. In the majority of cases, the consequences become apparent after several thousands of hours of operation and lead to the reduction in the useful life of the key engine components, affecting both the performance and the reliability of the engine.