Dr. Luis Fernández Ruiz-Morón is a project manager at Repsol’s R&D Centre and is also responsible for the tribology section. He recently attended the LUBMAT 2016 conference as a keyspeaker. During this interview, Fernández Ruiz-Morón explains how important it is to manage lubrication properly.

1.- Environmental regulations are being tightened up, more advanced formulations are being developed and the industrial sector is exploring new pathways to become more efficient and competitive. These are some of the reasons that are transforming the lubricant market. What is this revolution actually all about?

Generally speaking, lubricants and the oil & gas sector are undergoing significant changes because due to the above mentioned factors. As the environment in which we operate is technically complex, it is becoming increasingly necessary to network via consortiums and multi-disciplinary teams. End users are demanding better performance: more protection for their machines and less oil changes. Environmental restrictions, on the other hand, are increasing and this limits the number of substances used in the formulation of lubricants. It means that equipment manufacturers are forced to make changes in their designs to reduce emissions carrying CO2, particles and other contaminants: new materials, processes, after-treatments, etc., that influence lubricant composition. Lastly, more and more people are asking for a simplification of specifications issued by manufacturers and international bodies such as ACEA or API.

2.- Tribology is playing a key role in the development of increasingly advanced lubricants, but how exactly?

Every tenth of a second matters in the struggle to reduce CO2 emissions. Advances made in lubrication systems are proving to be the most cost-effective way of doing things. But not only that: Machines and motors that are more efficient, ecological and advanced require more complex lubricants: they must be compatible with biofuels and their negative effects in terms of friction control, and must adapt to downsizing and increases in thermal stresses. They must feature friction modifier systems for protection against wear in the so-called ultra-light grades and must be capable of dealing with systems such as start-stop that multiply events beyond the range of hydrodynamic lubrication, just to mention a few examples. Mention must also be made of the progress made in terms of surface coatings and which has made it necessary to readdress lubricant formulations.

3.- How would a company benefit nowadays from decidedly putting its stakes on incorporating lubrication management to its value chain?

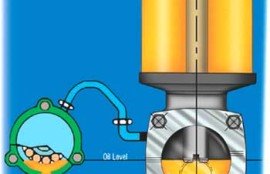

For many years, users have rated lubricants as a “process constant” with which you had to coexist and adapt to. Nowadays, we have over 1,000 lubricant references adapted to different applications. Many of these lubricants have been exclusively developed for specific customers who have managed to increase production, improve efficiency or reduce maintenance costs by incorporating lubricants with suitable bases and additives via an in-service oil monitoring system.

4.- Some of the most outstanding European experts attended the LUBMAT conference held in Bilbao on June 7. What would you underscore about this edition of the conference?

As this is my hometown, I feel extremely proud to say that this international conference hosted by UCLA and IK4-TEKNIKER has not only become an outstanding event over the years but also a must for professionals working in the field of lubrication and maintenance, equipment manufacturers, scientists, tribologists, chemical engineers, physicists… Not only because of the quality and novelty of the presentations, but also because of the opportunity offered in terms of networking in a privileged setting like Bilbao (in this edition).

5.- You were one of the keynote speakers. Could you briefly summarise some of the issues you discussed in your presentation?

As I’ve already spoken about the environment and the situation we are currently dealing with, I would now like to say something about how these environmental, economic, political and technical changes have affected lubricant formulations. In particular, we have reviewed the use of synthetic bases, new friction modifiers and activation systems. We have also addressed the complexity of the current specifications (the new ACEA 2016), the phenomenon of LSPI (Low Speed Pre-Ignition), fuel economy property testing and performance durability.